This article will introduce the names, functions, composition structures, and installation positions of automotive sensors, allowing readers to gain a basic understanding of them.

Coolant temperature sensor, consisting of a negative temperature coefficient thermistor, is installed on the cooling water passage to measure water temperature.

The water temperature sensor,it is a thermistor-based temperature sensor consisting of a negative temperature coefficient thermistor, which is installed on the instrument panel to measure water temperature.

The interior and exterior air temperature sensors are composed of negative temperature coefficient thermistors and are installed under the windshield inside the vehicle and inside the front bumper outside the vehicle, respectively, for measuring the interior and exterior air temperatures.

The intake temperature sensor is composed of a thermistor and is installed inside the air flow meter or air filter, as well as in the intake manifold and intake duct, for measuring the intake temperature.

The evaporator exit temperature sensor is composed of a thermistor and is installed on the air conditioning evaporator plate, used to measure the temperature of the air conditioning evaporator exit.

Exhaust temperature sensor, composed of a thermistor, is installed on the hot junction, fuse, and ternary catalytic converter, used to measure exhaust temperature.

EGR monitoring temperature sensor, composed of a thermistor, is installed on the EGR air intake manifold to monitor the temperature of the EGR cycle gas and the operation status of the EGR.

Paraffin-type gas temperature sensor, composed of paraffin, is installed on the carburetor-type engine air intake manifold. It functions as an air temperature regulation device at low temperatures and regulates idle speed at high temperatures.

Bimetal-type air temperature sensor, made of metal sheets, is installed on the carburetor-type engine air intake manifold. It is used for air temperature regulation at low temperatures and for idle speed correction at high temperatures.

Radiator cooling fan sensor, made of thermo-sensitive ferrite, is installed on the radiator and used to control the speed of the radiator fan.

Transmission oil temperature sensor, composed of thermo-sensitive resistors, is installed on the hydraulic valve body to measure the oil temperature and provide temperature information to the ECU for gear shifting, lock-up clutch engagement, and oil pressure control.

Vacuum switch sensor, consisting of a diaphragm and a spring, is installed on the air filter to detect whether the air filter is clogged.

Oil pressure switch sensor, consisting of a diaphragm and a spring, is installed on the main oil supply line of the engine to detect the oil pressure of the engine.

Brake master cylinder oil pressure sensor is a semiconductor type, installed at the lower part of the brake master cylinder, and is used to control the oil pressure of the brake system.

Absolute pressure sensor is a silicon diaphragm type, installed in the suspension system, used to detect the oil pressure of the suspension system.

Relative pressure sensor is a semiconductor type, installed on the high-pressure tube of the air conditioner, used to detect the refrigerant pressure.

Semiconductor piezoresistive pressure sensor is composed of semiconductor piezoresistive elements, installed on the intake manifold, used to detect the intake pressure.

Vacuum diaphragm type intake pressure sensor is composed of a vacuum diaphragm and a transformer, installed on the intake manifold, used to detect the intake pressure.

Capacitive pressure sensor is a diaphragm type sensor that is installed on the intake manifold and used to detect intake pressure.

Surface acoustic wave (SAW) pressure sensor is a type of pressure sensor that uses a piezoelectric substrate. It is installed on the intake manifold and is used to detect the intake pressure.

Turbocharger pressure sensor, composed of silicon diaphragms, is installed on the turbocharger to detect the boost pressure.

Brake master cylinder pressure sensor, a semiconductor type, is installed at the lower part of the main oil cylinder to detect the output pressure of the main oil cylinder.

Vane-type air flow sensor, composed of vanes and potentiometer, is installed on the intake manifold to detect the amount of air intake.

Karman vortex air flow sensor, composed of vortex generator, ultrasonic generator, photoelectric tube, is installed on the intake manifold to detect the amount of air intake.

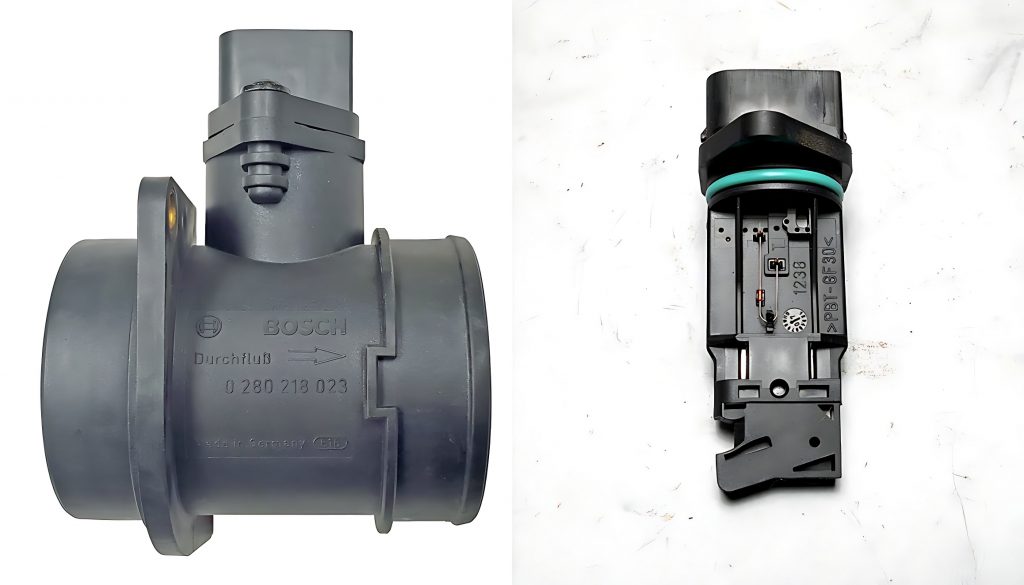

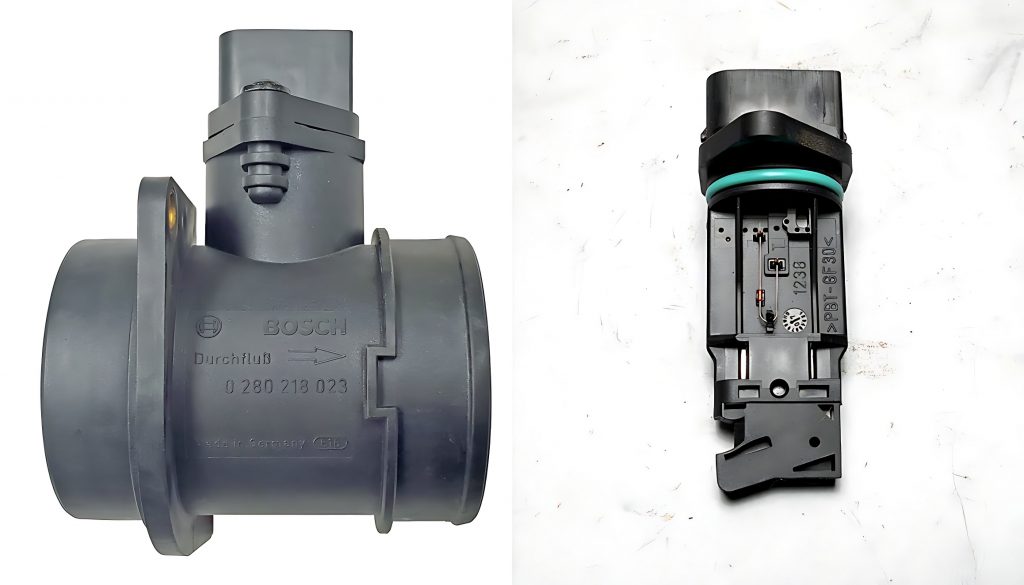

Hot wire air flow sensor, composed of platinum hot wire, is installed on the intake manifold to detect the amount of air intake.

Thermal film air flow sensor is a heating element made of thin metal fixed on a resin film, which is installed on the intake manifold to detect the amount of air intake.

Core type air flow sensor consists of a core and a potentiometer, which is installed on the intake manifold to detect the amount of air intake.

Zirconia oxygen sensor consists of a zirconia tube and a heating element, which is installed on the exhaust pipe or three-way catalytic converter to control the air-fuel ratio.

Titania oxygen sensor consists of a titanium tube and a heating element, which is installed on the full range air-fuel ratio sensor.

Smoke concentration sensor consists of a light-emitting element, a photosensitive element, and a signal circuit, which is installed in the cabin to purify the air.

Magnetic pulse type crankshaft position sensor (tooth) consists of a signal rotor, a permanent magnet, and a coil, which is installed in the distributor or at the front end of the crankshaft after the pulley, to detect the crankshaft angle position and measure the engine speed.

Magnetic pulse type crankshaft position sensor (rotor) consists of a timing rotor, G and Ne coils, which is installed in the distributor, to detect the crankshaft angle position and measure the engine speed.

Photoelectric type crankshaft position sensor consists of a crankshaft angle sensor and a signal disk, which is installed in the distributor, to detect the crankshaft angle position and measure the engine speed.

Trigger vane type Hall crankshaft position sensor consists of inner and outer signal wheels, which is installed at the front end of the crankshaft, to detect the crankshaft angle position and measure the engine speed.

Synchronous signal sensor (also known as camshaft position sensor), consists of a pulse ring and a Hall signal generator, which is installed in the distributor, to detect cylinder identification signal.

Thin-film oxygen sensor, made of zirconia solid electrolyte, is installed on the three-way catalytic converter to measure the oxygen concentration in the exhaust and control the air-fuel ratio.

Magnetostrictive knock sensor, which is composed of a magnetic core, a sensing coil, and a permanent magnet, is installed on the engine cylinder block to detect knock signals and input them to the ECU.

Resonant piezoelectric knock sensor, which is composed of a piezoelectric element and an oscillating plate, is installed on the engine cylinder block to detect knock signals and input them to the ECU.

Non-resonant piezoelectric knock sensor, which is composed of a balancing weight and a piezoelectric element, is installed on the engine cylinder block to detect knock signals and input them to the ECU.

Linear output throttle position sensor, which is composed of idle contact, full open contact resistor, and wire, is installed on the throttle body and connected to the throttle to determine the engine operating condition and control the fuel injection pulse width.

Switch type throttle position sensor, which is composed of IDL contact, PSW power contact, cam, and wire, is installed on the throttle body and connected to the throttle to determine the engine operating condition and control the fuel injection pulse width.

Rolling ball impact sensor, which is composed of rolling ball, magnet, guide cylinder, and contact, is installed in the following positions: on both sides of the fender; under the front headlamp bracket on both sides; on the left and right sides of the radiator bracket; below the dashboard and glove box of the driver’s cab, or in the central position in front of the vehicle body. It is used to detect the acceleration of the vehicle.

Rolling shaft impact sensor, which is composed of rolling shaft, contact, and leaf spring, the installation position and function is same as rolling ball impact sencsor.

Offset hammer impact sensor, which is composed of offset hammer, arm, contact, spring, and shaft, is installed in the same positions and has the same functions as the rolling shaft impact sensor.

Mercury switch impact sensor, which is composed of mercury and electrodes, is installed in the same positions and has the same functions as the rolling ball impact sensor.

Resistive strain gauge impact sensor, which is composed of electronic circuit, strain gauge, vibration block, and buffering medium, is installed in the same positions and has the same functions as the rolling ball impact sensor.

Non-contact torque sensor, which is composed of a coil and a torsion bar, is installed on the steering axis to measure the relative torque between the steering wheel and the steering gear.

Sliding variable resistor torque sensor, which is composed of potentiometer, slip ring, gear, and torsion bar, is installed on the steering axis to measure the relative torque between the steering wheel and the steering gear.

Photoelectric body height sensor, which is composed of photoelectric coupling element, shutter disk, and axis, is installed on the shock absorber rod of the suspension system to convert the height of the vehicle body into an electrical signal and input it into the ECU.

Seat position sensor, which is composed of Hall element and permanent magnet, is installed on the seat adjustment device to adjust the seat state.

Orientation sensor, which is composed of a coil and an iron core, is installed on the GPS terminal to navigate the vehicle.

Tongue-reed switch type speed sensor, which is composed of a tongue-reed switch and a magnet, is installed on the output shaft of the transmission or in the combination instrument to measure the speed of the vehicle.

Photoelectric coupling type speed sensor, which is composed of a photoelectric coupler and a rotor, is installed in the combination instrument to measure the rotation speed of the transmission input shaft.

Electromagnetic type speed sensor, which is composed of a rotor and a coil, is installed on the output shaft of the transmission to measure the rotation speed of the transmission input shaft.

O/D direct gear clutch speed sensor is the same as the speed sensor.

Electromagnetic wheel speed sensor is composed of a sensing head and a tooth ring, which is installed on the input shaft of the transmission to detect wheel speed.

Hall-effect wheel speed sensors are composed of Hall elements, trigger tooth rings, and permanent magnets. They are installed on the wheels, reducers, or transmissions to detect wheel speed.

Sunlight sensor is composed of photoelectric tube and filter, which is installed under windshield glass and on the upper side of instrument panel. It can transform sunshine condition into current and correct the inside temperature of the car.

Photoelectric light quantity sensor is composed of cadmium sulfide, ceramic substrate, and electrode. It is installed in the light controller above the instrument panel for the automatic control of car lights.

Photoconductive diode-type light sensor is composed of photoconductive diode and amplifier. It is installed on the instrument panel and can receive external light to detect the brightness around the vehicle. It can automatically control the brightness of the headlights.

Raindrop sensor is composed of vibrating plate, piezoelectric element, and amplification circuit. It is installed on the engine cover to detect rainfall and control the speed of the wiper.

Strain gauge pressure sensor is composed of semiconductor piezoresistive elements. It is installed above the oil pressure control component to detect the pressure of the oil pressure control component.

Air conditioning pressure switch sensor is composed of diaphragm, movable contact, fixed contact, and temperature sensing package. The high-pressure pressure switch is installed on the high-pressure piping to control the high-pressure pressure switch. When the pressure in the high-pressure circuit exceeds the specified value, the compressor will be shut down. The low-pressure pressure switch is installed on the low-pressure piping to control the low-pressure pressure switch. When the pressure in the high-pressure circuit is lower than the specified value, the compressor will be stopped.